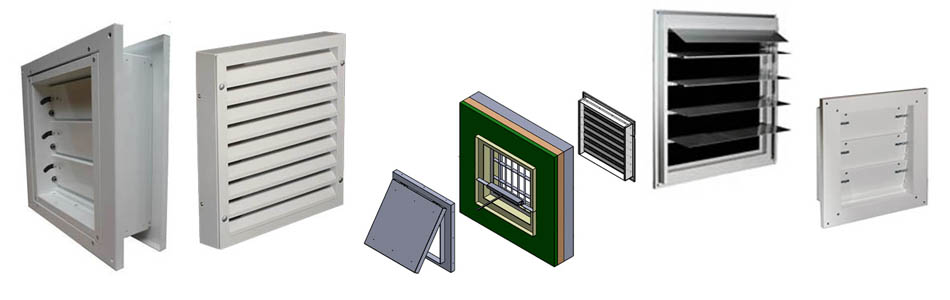

Pressure Relief Vents

These world leading Pressure Relief Vents offer 100% efficiency at 95 Pascal’s with a Dynamic Co-Efficient Factor of 1.15 compared to an open hole.

The High-X SHX and DUX AFP Air Technologies Gaseous Extinguishing System Pressure Relief Vents are the highest performing vents in the world. The unique interlocking Aerofoil balanced weighted blade system of the SHX single flow vent for Inert Gas Systems means that the vent blades start to open at 80 Pascals and are 100% open at 95 Pascals. Only 15 Pascals difference between partially open and 100% efficient which no other pressure relief vent can offer. The DUX dual flow vent mechanism allows vent blades to pivot in both directions catering for Halocarbon which create negative and positive pressure on discharge.

The AFP Air Technologies Pressure Relief Vents are the only third party verified vents on the market having undertaken live discharge performance testing by the world renowned UK Building Research Establishment (BRE). These world leading Pressure Relief Vents offer 100% efficiency at 95 Pascal’s with a Dynamic Co-Efficient Factor of 1.15 compared to an open hole. The AFP Pressure Relief Vents also come with some fire rating credentials having achieved a 4 hour fire integrity rating to EN 1363-1 & 2. Other credentials include testing to UL555 and STAM E 119-08a.

SHX Models:

The SHX single direction Pressure Relief Vent is designed for Inert Gas Systems that produce only positive pressure on discharge. The secret to the AFP vent performance is the unique interlocking Aerofoil balanced weight blade system. BRE testing demonstrated the vents characteristic of starting to open at 80 Pascals of enclosure pressure and is 100% efficient at 95 Pascals. Only 15 Pascals difference needed to achieve full vent efficiency.

The SHX range of vents comes in 4 standard sizes and all vent sizes have been validated for actual Free Vent Area (FVA) when fully open. No other vents can offer such accuracy meaning nothing is left to chance when using an AFP Pressure Relief Vent for your gaseous extinguishing system installation. The issue with current practices used in the fire industry see’s vents installed with varying Resistance to Open Pressures (RTOP). The ideal pressure relief vent should resemble a hole in a wall that can be sealed up once a gaseous system has been discharged. The greater that RTOP value of the vent means the greater back pressure that will be experienced on discharge. Having worked out your vent area required for your risk is only one half of the equation to installing a proper pressure relief venting system. Fire Protection Technologies can assist in determining precisely your pressure relief venting requirements without leaving anything to chance.

DUX Models:

The DUX multi-directional Pressure Relief Vent has been uniquely designed for Halocarbon agents to ensure that over or under pressures on discharge are capped below the structural integrity limit of your enclosures. Not many consultants, designers or end users are aware of the magnitude of the negative or positive pressures that Halocarbons can create on discharge. In fact in most situations all Halocarbons produce greater negative pressure on discharge than positive (humidity dependant). Therefore you need a multi-directional pressure relief vent that can cater for pressures in both directions.

The DUX model of vents has a unique mechanism that allows vent blades to pivot from one direction to the other in a single vent design. No need to install separate vents to cater specifically for negative and then positive pressure as the DUX model can perform this task in one vent design. Fire Protection Technologies can quantify the Free Vent Area needed in both directions for any Halocarbon using current industry formulas for all Halcarbons (FM-200, NOVEC 1230, ECARO 25) so nothing is left to chance.

DMX Models:

The DMX is a 2 hour fire rated, ultra high sealed, modular two way pressure vent specifically designed for FK-5-1-12 (Novec).