Explosibility Testing

Brochures

B9018 Explosion Protection Testing Services

Fike offers a wide range of explosibility tests designed to assist companies in identifying and mitigating costly explosion hazards.

Brochures

Fike offers a wide range of explosibility tests designed to assist companies in identifying and mitigating costly explosion hazards.

Explosibility testing provides a basis for safe plant design, operating parameters, and handling procedures. In conjunction with our explosion protection partners, Fike Corporation, we offer a wide range of explosibility tests designed to assist companies in identifying and mitigating costly explosion hazards. Fike’s ‘state of the art’ testing laboratory is staffed with highly trained technicians, engineers, and combustion scientists; and tests are conducted in accordance with ASTM and CEN standards to assure proper execution and interpretation.

The potential severity of a dust explosion is quantified by measurement of the pressure and rate of pressure rise due to the explosion.

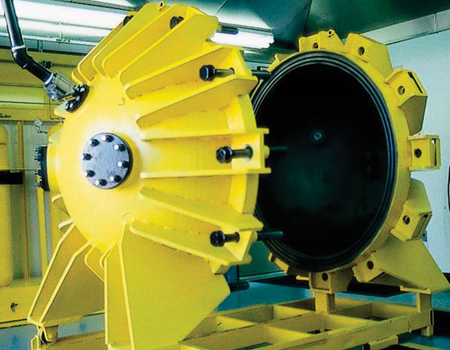

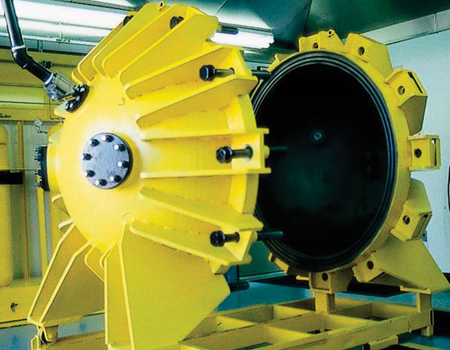

The explosive capability of the explosion behavior of a dust sample can be determined in a 20 liter spherical vessel.

The explosive behavior of dusts can be described by the maximum explosion pressure (Pmax), the maximum rate of explosion pressure rise (KSt), the minimum explosive concentration (MEC) and the maximum oxygen concentration to prevent explosions.

The standard test method is ASTM E1515, “Standard Test Method for Minimum Explosible Concentration of Combustible Dusts".

The first step in a process hazard analysis is determining the nature of the hazard.

The lowest thermal ignition energy is referred to as the "minimum auto-ignition temperature" (MAIT).

The processing of powders and bulk solids requires a consideration of the dust explosion risk. A part of this consideration must be the ignition characteristics of the dust, as the relative susceptibility to ignition determines the required prevention measures for a given process.

The accumulation of dust in layers is common in industrial facilities handling combustible dusts and can pose fire or explosion hazards. Dust layers that are exposed to hot surfaces can ignite, provoke a fire, and/or initiate a dust explosion.

Most dust samples contain a wide range of particle sizes; however, it is the finer particles that are more likely to become lifted and create an explosion hazard.